Tips & Tricks

Roll vs. Cut Thread – A Full Breakdown

Most threaded fasteners can have their thread either cut or rolled. Each method has their own advantages as well as disadvantages, along with a combination of differences and misconception.

Painting the Tips of NexGen2™ Bolts

For use in the telecommunications industry, our tower bolts range from the NexGen2™ Blind Bolt Assembly, U-Bolts, J-Bolts, Step Bolt Adapters and Structural Bolts. Applications range from one-sided installation of structural bolts to no-weld installation processes for tower modifications.

Understanding Options for Corrosion Resistance

Building fastener corrosion can weaken or ruin fastening strength over time causing structural damage. This makes the selection of fasteners crucial. Many factors affect fastener durability, among them: fastener composition, platings and the environment.

Threaded Rods Use Outside of the Construction Industry

In the telecommunications industry, where cell tower modifications are king, threaded rod, also called anchor studs, see use in a multitude of applications, but the most common is anchor bolting.

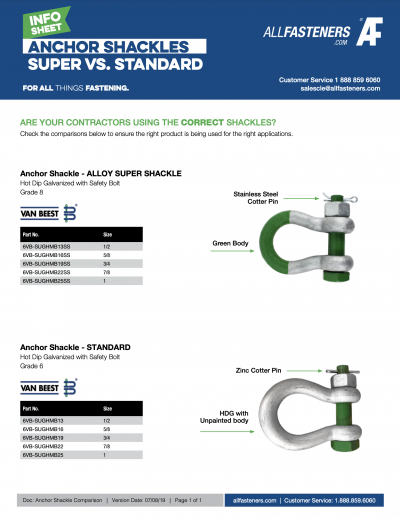

Make Sure to Use the Correct Turnbuckles and Anchor Shackles?

Due to the recent recalls in the industry surrounding anchor shackles, AF Tower asks the question, “are you using correct Van Beest shackles and turnbuckles that are specified?"

Save Time and Money with Cold Galvanizing

Protecting your metal, mainly steel, structures from corrosion, dust or any environmental element has been sought after for decades. One of the most used techniques for doing such a thing has been galvanizing, due to its ability to extend the lifespan of the materials through a protective barrier.

Metal Shims: Their Use in the Industry

Most consumers know shims to be made from solid polypropylene, and that they are ideal for window and door frame leveling, plus floor joist, wall and ceiling batten or joinery packing. What most consumers may not know is that these polypropylene shims have a metal counterpart for use in other industries.

The Importance of Pull Testing

For anchor bolts, eyebolts, scaffolding and threaded rod embedment, the best way to test the fasteners strength and durability is by performing a pull test. And the best way to perform a pull test is with a pull tester.

How to Get the Most Out of Your Aviation Snips

Aviation snips typically have three different colored handles – red, green and yellow – and this is not to make them look more appealing to the eye. Instead this color coding actually informs the user as to what each specific tool is capable of doing.

Screw Anchors – The Removable Concrete Anchoring Solution

When it comes to general fastening applications into concrete most might not know what to use. Unlike other substrates that have a ton of tools and options for completing such tasks, concrete requires a more unique type of fastener to get the job done – the conveniently named concrete anchor.